Facial Prosthetic Materials

A primary focus in biomaterials research at the UNMC College of Dentistry is the development of facial prosthetic materials. For people who have suffered severe head trauma, extensive loss of tissue or bone from head and neck cancer, or birth defects, surgery alone cannot correct the facial deformities. Artificial replacements, such as ears, noses, or eyes, cover these defects and help restore facial appearance.

Our research is aimed at developing long-lasting and color-stable artificial replacements. This research will improve the quality of life for those who endure facial disfigurement.

Dr. Mark W. Beatty leads this research.

Tour the Biomaterials Research Lab

|

An artificial ear that has lost its color and has undergone surface peeling after only three months of usage. Unfortunately current materials fade and deteriorate quickly. |

|

| Materials are tested in this preparation room using cut-off sectioning saws, a grinder (black), auto-polisher and porcelain oven. the preparation of materials is important for further testing of surface and physical properties. |

|

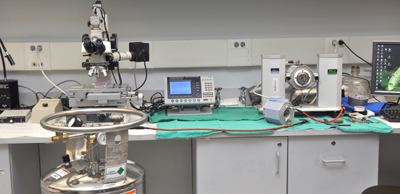

| Following material preparation, one of the next stages in our lab can be using equipment for materials characterization: 3-D measuring microscope with CCD camera (left), for measuring dimensions with precision to 0.5 micrometers. The dynamic mechanical analyzer (right) with liquid nitrogen tank attachment (foreground) measures viscoelastic properties. |

|

Servohydraulic machine equipped testing dynamic properties, including cyclic and creep testing of materials and tissues. |

|

Electromechanical testing machine with environmental chamber (for heat and cold environments in the background) and computer control (foreground) for stress-strain tests. This allows evaluation of flexibility, stiffness, and strength of materials. |

|

Surface analysis room with microhardness testers, used in further evaluation of surface properties. |

|

Pin-on-disc tribotester for testing friction and wear of materials. |

|

Ultraviolet radiation boxes housed in a walk-in environmental room with heat and humidity controls to simulate accelerated outdoor weathering. Affects color, elasticity, and surface texture among other properties. |