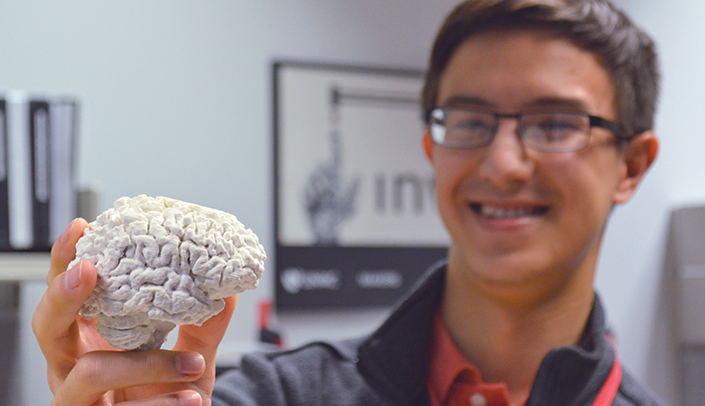

Brandan Lew is making a model of his brain.

His actual, individual brain.

Lew, a first-year medical student on the M.D./Ph.D. track, had an MRI taken on a previous rotation, and now is watching one of UNMC’s 3-D printers use the file to build his brain, bit by plastic filament bit.

He’d just gotten done with an exam, on a recent morning, and stopped by the McGoogan Library of Medicine to see how his brain was coming along. It might take 20 hours, total.

And sometime during those 20 hours, Lew also joined the UNMC Makers, a student group dedicated to 3-D printing. The Makers have an official workspace in the McGoogan Library, sharing an office with the 3-D printers themselves. In addition to infrastructure, the printers and group enjoy generous funding from the library.

“From the very first time I met the students, I knew this was a student group we wanted to support,” said Emily McElroy, the library’s director. “Using technology funds, we were able to follow through by ordering a 3-D printer and scanner. Since then, we’ve increased the space to accommodate additional printers and related technology.”

And the Makers are invigorated by all the possibilities the technology provides.

“There’s almost nothing we can’t do,” said Tim Bielecki, a graduate student in the Cancer Research Graduate Program.

If you have a design, the Makers – and printers – can make it. Need a prototype? Let’s get to work.

Or, need one lousy replacement part for something in the lab, but you’d have to buy a whole set – at high cost – to get it? Or worse, they don’t even make that model anymore?

The Makers can make one, for pennies on the dollar.

The items they make can be as simple as a missing spare part or as complicated as the human brain.

Surgeons can make 3-D models off of MRIs, then take their time to study what they will be working on before opening the patient.

Seeing the engineering behind everything – in part, by having to make it – is exciting, Bielecki said.

“That’s the thing about science,” he said. “It’s fun to learn how to do things – why you do things.”

And part of their mission is passing on that love of science to even younger students.

The Makers are taking lenses from disposable cameras to make inexpensive microscopes for distribution to local elementary schools.

Will Payne, an officer of UNMC’s 3-D Maker’s Club, prepares one of the competitors’ presentations on the iEXCEL center’s MultiTaction Wall, behind the 2016 Invent-a-Thon trophy, a 3-D-printed model of a light bulb that is lit with LEDs.

Outreach efforts continued during the recent Nebraska Science Festival, when the Makers and McGoogan Library teamed up with UNMC’s technology transfer and commercialization office, UNeMed, to sponsor the inaugural 3-D Printing Invent-a-Thon.

Participants had to come up with a device developed and 3D-printed in less than a day. All three participating teams were from local high schools and were tasked to deliver a solution that would help people who suffer from multiple sclerosis. All teams were given two days to research the problem, develop a concept and then design and print a prototype.

Harrison Pruitt, 17, and Ryan Hendrickson, 17, of Millard South High School, won first place for an exoskeleton that would help MS patients walk more easily. Their prototype resembled a jointed leg brace with a solid support strapped to the outside of the leg, from the heel to just above the knee. Their device would include servomotors that would provide the wearer powered-assistance when walking.

The runner-up designs also focused on helping MS patients’ difficulty with walking. One team proposed a counter-balancing device that would help offset the wearer losing balance. The other device was a self-contained seating system that strapped to the legs so the wearer could sit and rest virtually anywhere.

“One team had their design and was ready to print in four hours,” said Tyler Scherr, a member of the Makers. The 30-year-old UNMC grad student, who completed his Ph.D. this spring, said, “It made me feel old.”

The winners’ trophy was 3-D printed, of course. It looked like a large light bulb mounted to a thick base. LED lights inside the base gave the bulb a soft glow.

Hendrickson said his teammate, Pruitt, should be the one to take the trophy home.

“He needs a lamp,” Hendrickson said.

Now, you can 3-D print them. And brains. Spare parts. Before long, human spare parts, too. The possibilities are endless.

All you need, Bielecki said, is a file, and the printers and the Makers can help make it a reality.

If you need to make something, ask the Makers. They’re at the library. Sixth floor.

“The students inspire the campus community by imagining ways to solve problems using these technologies to meet their research and learning needs,” McElroy said. “Supporting the UNMC Makers has been a highlight for me and everyone else in the library.”